The Process of Manufacturing Plastic Pots by Injection: Details of Art and Technology

The manufacture of plastic pots by injection is a fascinating process that combines technical precision with creativity. In this article, we are going to dive into the details of this process to discover how plastic is transformed into the pots we use in our gardens and homes.

Injection molding:

Injection molding is the heart of the plastic pot manufacturing process. It begins with the preparation of the molds, which determine the shape and size of the pots. These molds are precision engineered to ensure consistency in every product manufactured.

- Material Preparation: Before injection, the plastic is heated at a high temperature until it reaches a liquid or semi-liquid state. This ensures that the plastic flows easily into the mold and is evenly distributed to create a high-quality pot.

- Material Injection: Once the plastic is in its proper state, it is quickly injected into the mold under high pressure. This injection process fills the mold with precision, ensuring that every detail of the planter is reproduced exactly.

- Cooling and Solidification: After injection, the mold is cooled to solidify the plastic. This step is crucial to ensure that the pot maintains its shape and structure once it is removed from the mold. Cooling time may vary depending on the type of plastic used and the size of the pot.

- Removing the Pot: Once the plastic has completely solidified, the pot is carefully removed from the mold. This process is carried out with precision to avoid damage to the pot and guarantee its final quality.

QA:

Throughout the injection manufacturing process, rigorous quality controls are carried out to ensure the integrity and functionality of each pot produced. From inspecting molds to evaluating finished pots, strict standards are applied to ensure customer satisfaction.

Advantages of the Injection Manufacturing Process:

- Efficiency: Injection manufacturing is a highly efficient process that allows mass production of plastic pots with high production speed.

- Precision: Injection molding technology ensures exact reproduction of every mold detail, resulting in consistent, high-quality pots.

- Design Flexibility: This process allows for a wide variety of designs and shapes, allowing for the creation of custom planters to meet customers' specific needs.

The manufacturing of plastic injection pots is a complex process that combines technical skills with advanced technology. From material preparation to removal of the final pot, each step of the process is performed with precision to ensure the quality and consistency of the final product. Thanks to this process, we can enjoy a wide variety of plastic pots. These pots are durable, functional and aesthetically attractive in our gardens and homes.

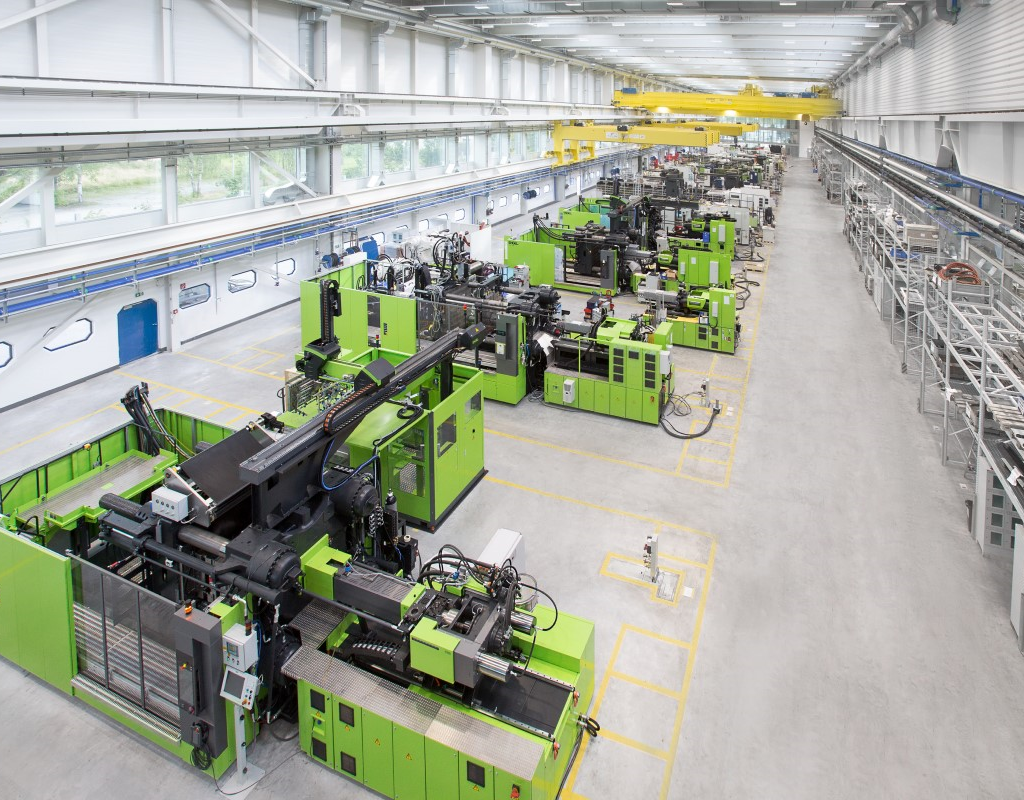

At Murgiplast we are experts in the manufacture of plastic pots for ornamental plants and agricultural boxes for fruits and vegetables using the injection process. We have a modern and constantly evolving factory with various injection machines that respond to the needs of the agricultural and ornamental world. Thus, our clients have the latest advances to be competitive in their specialties.